High Temprature Spark Plasma Sintering System

The High Temperature Spark Plasma Sintering System is a state-of-the-art device designed for advanced materials processing, specifically aimed at researchers and manufacturers in the fields of metallurgy, ceramics, and composites

Product Description

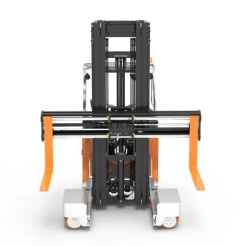

High Temperature Spark Plasma Sintering System

Product Overview

The High Temperature Spark Plasma Sintering System is a state-of-the-art device designed for advanced materials processing, specifically aimed at researchers and manufacturers in the fields of metallurgy, ceramics, and composites. This system leverages the spark plasma sintering (SPS) technology to achieve exceptional densification and microstructural control at high temperatures, making it essential for producing high-performance materials.

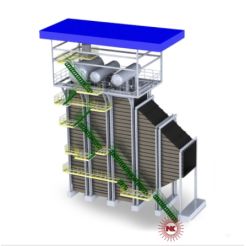

Key Specifications

- Temperature Range: Up to 2000°C for versatile material applications.

- Pressure Capability: Up to 100 MPa to ensure optimal material consolidation.

- Sinters in Minutes: Rapid heating rates, significantly reducing process time compared to conventional sintering.

- Chamber Dimensions: 50mm to 100mm (custom sizes available upon request).

- Weight: Approximately 200 kg, designed for both lab and industrial settings.

Unique Features

- Advanced Control System: Integrated AI-driven controls for real-time monitoring and adjustments, ensuring optimal sintering conditions.

- Variable Heating Rates: Customizable heating profiles to accommodate different material types and desired properties.

- High Vacuum Capability: Reduces contamination and improves material purity during processing.

- Material Flexibility: Capable of sintering a wide range of materials, including metals, ceramics, and composites.

- User-Friendly Interface: Intuitive touch-screen display for ease of operation and data logging.

Materials and Durability

- Premium Quality Components: Built with high-grade alloys and ceramics to withstand extreme temperatures and pressures, ensuring durability and longevity.

- Corrosion-Resistant Design: Enhanced protection against oxidation and wear, ideal for demanding environments.

Performance Metrics

- Efficiency: Reduced energy consumption compared to traditional methods by up to 30%, leading to cost savings.

- Speed: Achieves sintering within 5-30 minutes, enabling quick turnaround for research and production.

- High Density Achievement: Attains density levels above 98% for superior material properties.

Problem Solving and Improvement

The High Temperature Spark Plasma Sintering System addresses the challenges faced in material processing by providing a rapid and efficient solution for achieving high-density materials. Its unique capability to control temperature and pressure with precision not only enhances the mechanical properties of the final products but also opens new avenues for material innovation. By investing in this system, users can reduce production times, improve material performance, and facilitate advanced research projects, ultimately leading to enhanced productivity and competitiveness in the market.

Transform your material processing capabilities with our High Temperature Spark Plasma Sintering System – where innovation meets efficiency!

Related Products:High Temprature Spark Plasma Sintering System, Hot Sale P4 Vacuum Hot-Pressing Sintering Furnace