Wear Resistance Plate

We have equipped with our own developed wear plate hardfacing machine, including single torch, double torch and quadrule torch wear plate hardfacing machine, total 25 uints hardfacing machine.

Product Description

SPECIFICATION

| Chemical Composition of Deposited Metal (Wt%) | ||||||

| Thickness | C | Si | Mn | P | S | Cr |

| 3+3 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-22 |

| 4+4 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-23 |

| 5+5 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 20-23 |

| 6+6 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 24-38 |

| 8+8 | 3.5-4.5 | 0.5-1.2 | 0.5-1.0 | - | - | 27-31 |

Wear Resistance Plate

Jinhua specializes in the production of wear resistant steel plates and regularly offers a wide range of grades and thicknesses as well as custom fabrication capabilities.

Wear-resistant steel plates for mining, excavation and heavy machinery manufacturing.

Wear-resistant materials are used in wear applications that require resistance to increased impact and sliding. Wear resistant materials are tested by hardness and wear resistance standards to measure the expected performance and life cycle of the steel plate in wear or abrasion resistant applications.

Applications

Because of its versatility and flexibility, you can use it for a wide range of applications. Wear-resistant steel sheets are commonly used in energy, industrial manufacturing, infrastructure and other applications. Other applications include:

Mining

Construction

Material handling

Features

Its most notable features include:

Excellent and extreme hardness

Outstanding service life

No compromise on structural properties

High toughness (resistance to cracking and deformation)

Consistency at high impact and high temperatures

Wear Resistance Plate Manufacturer

We have equipped with our own developed wear plate hardfacing machine, including single torch, double torch and quadrule torch wear plate hardfacing machine, total 25 uints hardfacing machine.

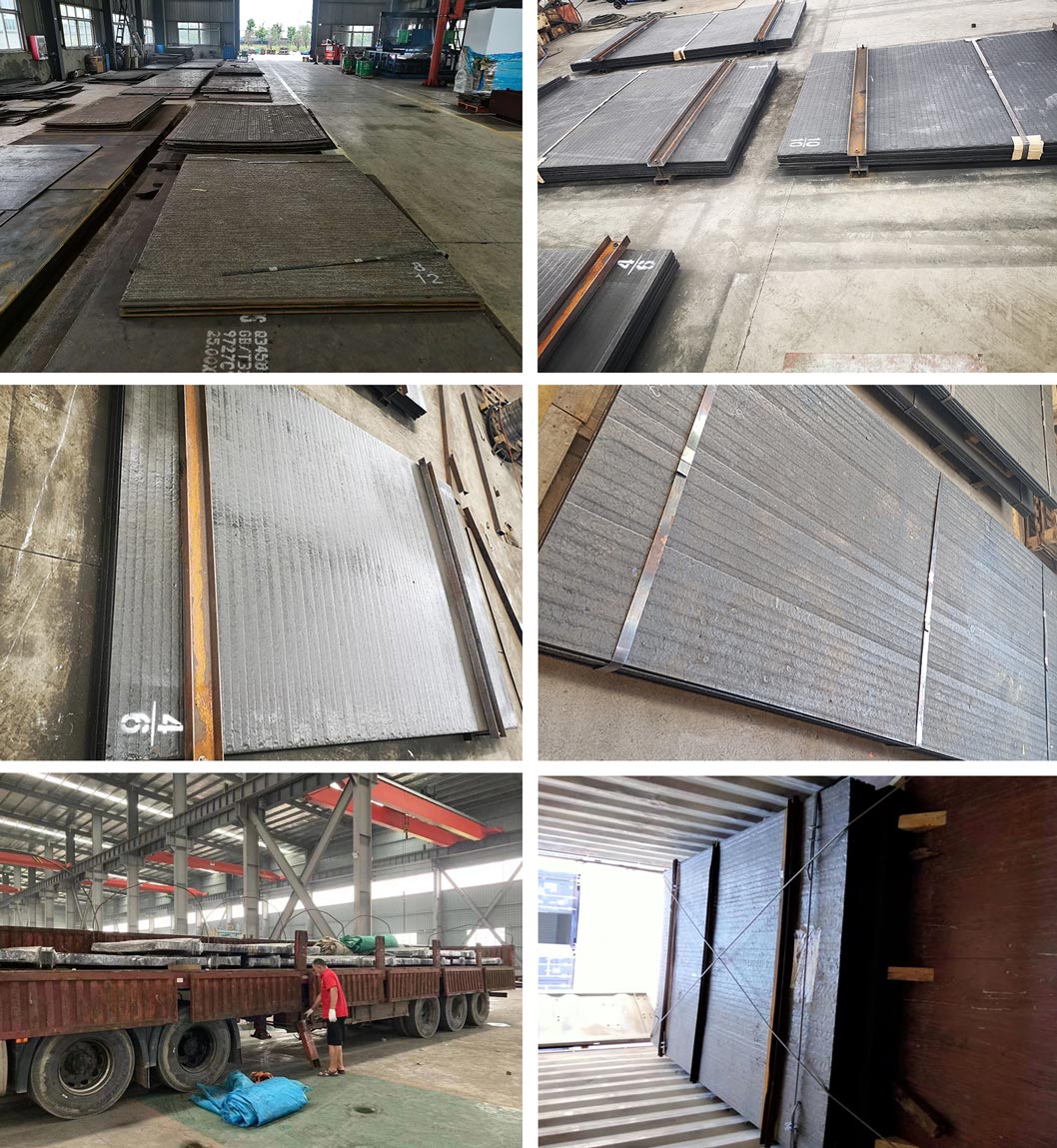

PICTURE