Tinplate

Tinplate refers to cold-rolled low-carbon thin steel sheet or strip coated with commercial pure tin on both sides. Tin mainly prevents corrosion and rust. It combines the strength and formability of steel with the corrosion resistance, solderability and beautiful appearance of tin in one material.

Product Description

Tinplate refers to cold-rolled low-carbon thin steel sheet or strip coated with commercial pure tin on both sides. Tin mainly prevents corrosion and rust. It combines the strength and formability of steel with the corrosion resistance, solderability and beautiful appearance of tin in one material. It is corrosion-resistant, non-toxic, and has suitable strength and processability. In addition to being used as the main material of metal packaging in the food packaging industry, tinplate is also widely used in many industries such as electronic components and batteries.

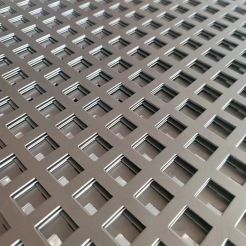

The cross-section structure of tinplate

Tinplate

Chrome-plated steel is a cold-rolled thin steel sheet that does not use tin as a coating. Its substrate is the same as tinplate, but its coating is surface treated by electrolytic chromic acid treatment. The upper layer of the coating is hydrated oxide of chromium and the lower layer is metallic chromium. Chrome-plated iron is widely used in upper and lower covers of metal containers, coated iron, etc. due to its outstanding paint adhesion and coating heat resistance.

The cross-section of chrome-plated iron:

Tin Free Steel

Performance characteristics: environmental protection, safety, consumption

Environmental protection : Tinplate is a steel metal product, which is a renewable resource that can be completely recycled and reused.

Safety : The sealing is complete, the contents do not require preservatives and other additives, and the shelf life is long, better than any other packaging materials.

Consumption : Tinplate cans have strong temperature conductivity and are perfectly suitable for heating and cooling.

Steel has high strength and hardness, is not easily deformed, and is suitable for transportation and storage.

Tinplate packaging has exquisite craftsmanship and rich colors, making it the most noble packaging material.

Customs knowledge on packaging materials:

Tin plate HS code: 7210120000 Illegal inspection of general goods

Chrome plate HS code: 7210500000 General goods illegal inspection

Packaging material classification

1) Tin-plated sheet: 1) SR ETP: primary cold-rolled tin-plated sheet 2) DR ETP: secondary cold-rolled tin-plated sheet

2) Chrome-plated sheet: 1) SR TFS: single cold-rolled chrome-plated sheet 2) DR TFS: double cold-rolled chrome-plated sheet

3) Tinplate substrate: Tinplate substrate without tin plating and chrome plating is mostly used for trial after painting or lamination.

Product Features

1. Characteristics of tinplate

1) Excellent corrosion resistance: Selecting the appropriate coating thickness can meet the corrosion resistance requirements of different contents

2) Excellent coating properties : can be printed with various coatings and inks

3) Excellent weldability: various cans can be made by welding (including brazing)

4) Excellent processability and strength: Selecting the appropriate tempering grade can meet the processing requirements and the strength after forming.

5) Bright appearance: The surface of the tinplate has a bright metallic luster. Select substrates with different surface states to obtain products with different surface roughness.

2. Chrome plate characteristics

1) Excellent coating adhesion: The coating adhesion is much better than that of tinplate, and can be used to manufacture DRD cans and glued cans

2) Excellent resistance to heat denaturation: resistant to high temperature baking, no discoloration, and no deterioration of material performance

3) Excellent anti-sulfurization performance: The metal chromium layer has good anti-sulfide performance and is suitable for canned protein-rich foods such as fish.

4) Excellent resistance to filiform corrosion: Excellent resistance to filiform corrosion under the paint film

5) Excellent alkali resistance: The chrome plating layer is a non-amphoteric material, which is more suitable for packaging of alkaline contents such as detergents and pigment dispersants.

3. Different characteristics of tin plating and chrome plating

1) Appearance: Even if the original plate with the same surface state is used, the surface appearance of the chrome-plated plate is different from that of the tin-plated plate, showing a unique metallic chrome luster.

2) Corrosion resistance: The printed chrome plate has excellent corrosion resistance, so it is usually printed on both sides, but depending on the type of contents, the inner surface of the can can also be coated with plain iron.

3) Brazing: Chrome-plated plates cannot be brazed.

4) Weldability: Chrome plating can be welded even if the metal chrome plating layer is removed, but the welding performance is inferior to tinplate.

5) Coating Weight: Chrome-plated plates generally have only one coating thickness product, while tin-plated plates have a range of thickness standards.

Performance comparison chart

Product Usage

1. Packaging of consumer and industrial products and other electronic components and stampings.

2. Tinplate: food cans, milk powder cans and top and bottom covers, beverage cans, aerosol cans, chemical barrels, twist-off caps (high caps), easy-open caps, miscellaneous cans, battery irons, electronic accessories, stamping parts.

Chrome plate: easy open cover, twist-off cover (high cover), fish cans, two-piece cans, bottle cap iron, food bottom cover, home appliance panel, ink can, deep-drawn filter element housing, barrel top bottom cover, shallow-drawn can.

3. Surface state: Different requirements for surface state are all target values for the surface roughness. The characteristics and uses are as follows. (Generally, B and R surfaces are the most common requirements)

|

Surface specification |

Designation |

Roughness (Ra value) Target range (um) |

Features and uses |

|

Superbright surface |

BE |

0.10-0.20 |

The brightest surface. |

|

Smooth surface |

B |

0.20-0.35 |

Bright surface. For general use. |

|

Rough surface |

R1 |

0.35-0.50 |

Stone surface. The scars produced in printing and canning are not conspicuous. |

|

Very rough surface |

R2 |

0.50-0.70 |

Coarse stone surface. |

|

Flat surface |

M |

0.70-1.20 |

Fine sandblasted surface. For crown or DI tank (tinplate without soft melting). |

|

Silvery surface |

S1 |

0.70-1.20 |

Fine sandblasted surface. Mainly used for art cans (limited to soft melting tinplate). |

|

Silk noodle |

SA |

1.80-3.00 |

Coarse sandblasted surface. Mainly used for art cans (limited to soft melting tinplate). |

Note: S1 is characterized by fineness and no rolling marks; the thick surface SA is also called frosted SA, which has a more obvious grainy feel. Both the S surface and the M surface require further processing and spraying.

4. Tempering hardness range and some uses are listed.

|

Rolling type |

Tempering degree |

Hardness range (HR30T) |

use |

|

Single roll |

T1 |

49±4 |

Deep drawing tank, mouth, etc., requiring high flexibility. |

|

T1.5 |

51±4 |

Deep drawing tank, mouth, etc., requiring high flexibility. |

|

|

T2 |

53±4 |

The general degree of deep drawing, the use of slightly required toughness. |

|

|

T2.5 |

55±4 |

For general use. It has the depth of T2 and the toughness of T3. |

|

|

T3 |

57±4 |

For general use. It has a certain toughness. |

|

|

T3.5 |

59±4 |

With strong toughness, it is used for the tank body or lid which requires the material between T3 and T4. |

|

|

T4 |

61±4 |

With strong toughness, it is used for tank body, upper and lower cover and crown cover. |

|

|

T5 |

65±4 |

For applications requiring excellent buckling resistance, tank body and upper and lower cover. |

|

|

Secondary rolling |

DR7M |

71±5 |

High strength food cans, beverage cans and other high strength applications. |

|

DR8 |

73±5 |

High strength food cans, beverage cans and other high strength applications. |

|

|

DR8M |

73±5 |

High strength food cans, beverage cans can body, screw cap and other high strength applications |

|

|

DR9 |

76±5 |

Screw caps and other high strength applications. |

|

|

DR9M |

77±5 |

Screw caps and other high strength applications. |

|

|

DR10 |

80±5 |

High strength applications such as pressing open caps. |

Note: Tinplate has a very wide range of uses, and the above table is for reference only.

Manufacturing process

1. Production process function introduction

2. Steelmaking: chemical composition, impurities.

3. Hot rolling: final rolling temperature, coiling temperature, thickness curve.

4. Pickling: remove iron oxide scale and achieve fixed width.

5. Cold rolling: Achieve cold-rolled strip with target thickness and excellent plate shape.

6. Degreasing: Remove grease residue on the surface after cold rolling.

7. Hood annealing/continuous annealing: recrystallization of steel plates can be achieved under controllable conditions.

8. Flattening: To achieve control of surface morphology and improve the quality of strip shape.

9. Tin plating/Chrome plating: To achieve control of coating electroplating and surface oil amount.

10. Horizontal shearing: realize horizontal shearing and wave shearing of strip steel.

Supply Specifications

1. Tinplate(ETF)

|

product type |

Product Brand |

Annealing method |

Tempering degree |

Thickness range (mm) |

Width range (mm) |

Length range (mm) |

Tinning amount range (g/m³) |

|

Tin Coil/Tin Plywood |

SPCC SPCE MR |

BA |

T1-T5 DR7-DR9 |

0.13-0.5 |

700-1000

|

500-1100

|

1.1-11.2 |

|

Tin Coil/Tin Plywood |

SPCC SPCE MR |

CA |

T3-T5 DR7-DR9 |

0.13-0.5 |

700-1000

|

500-1100

|

1.1-11.2 |

|

Delivery status |

Coil weight |

Coil Packaging Method |

Plywood weight |

|

Rolled plate/plywood |

4-8 tons |

Horizontal/Vertical |

1-2 tons |

Chrome plate (TFS)

|

product type |

Product Brand |

Annealing method |

Tempering degree |

Thickness range (mm) |

Width range (mm) |

Length range (mm) |

Tin plating amount range (mg/m³) |

|

Chrome plated coil/chrome plated plywood |

SPCC SPCE MR |

BA |

T1-T5 DR7-DR9 |

0.13-0.5 |

700-1000

|

500-1100

|

50-150 |

|

Chrome plated coil/chrome plated plywood |

SPCC SPCE MR |

CA |

T3-T5 DR7-DR9 |

0.13-0.5 |

700-1000

|

500-1100

|

50-150 |

|

delivery status |

Coil weight |

Coil Packaging Method |

Plywood weight |

|

Rolling |

4-8 tons |

Horizontal/Vertical |

1-2 tons |

Product packaging

1. Packaging material specifications:

|

Serial number |

Material Name |

Specifications |

Technical indicators |

|

1 |

External anti-rust paper |

|

1. Moisture permeability requirement ≤7g/m2 * 24 hours; 2. Unit weight 170±10g/ m2 3. Others shall be carried out in accordance with the manufacturer's standards. |

|

2 |

Galvanized inner corner guard |

Supply |

|

|

3 |

Galvanized outer corner guard |

Supply |

|

|

4 |

Plastic inner protection plate |

Thickness 2.0 |

1. Product thickness tolerance ±0.15; 2. Surface color shall comply with Party A's requirements, without obvious appearance defects, and the printing shall be clear and accurate; 3. Simply supported beam impact strength ≥18KG/M2 without breaking; Bending strength ≥12MP. (bend 90 degrees for more than 5 times without breaking). |

|

5 |

Plastic outer protection plate |

Thickness 2.0 |

Same as above |

|

6 |

Plastic end guards |

Thickness 2.0 |

Same as above |

|

7 |

Paper outer corner protector |

2. 5 * ( 60 + 40) |

1. Thickness tolerance ±0.05; 2. No obvious defects in appearance |

|

8 |

Pearl cotton |

Thickness 2.0 |

1. Thickness tolerance ±0.05; 2. No obvious defects in appearance |

|

9 |

plastic film |

Thickness 0.0 8 |

|

|

1 0 |

Steel belt |

0.9*32 |

National standard medium-strength steel strip, tensile strength ≥ 5 50N/mm2 ; elongation after fracture (%) ≥ 3; the product requires blueing or above surface treatment. |

|

11 |

Adhesive tape |

60 |

Duct tape and plastic tape |

|

1 2 |

Plastic gasket |

90*90 |

|

|

13 |

Galvanized lock |

0.9*32*45 |

|

|

14 |

Wooden pallet |

|

Fumigation wooden pallet (foreign) Wooden pallet (domestic) |

Note: Different factories have different requirements for packaging.

Use suggestions

1. Precautions for using tinplate

1) Since the coating of tinplate is soft metal tin, appropriate protective measures should be taken to avoid scratches during transportation.

2) Since the corrosion resistance, paintability, weldability and mechanical properties of tinplate are time-sensitive and will change over time, please use it as soon as possible after receiving it.

3) Although tinplate has excellent corrosion resistance, it may still rust in a humid environment, so use it as soon as possible after opening the package.

4) Since tin is soluble in alkaline solvents, the inner surface of tinplate needs to be coated when it is used to package alkaline contents.

5) Sulfide-containing contents will cause the surface of the tinplate to turn black, and the inner surface needs to be painted.

2. Precautions for using chrome-plated plates

1) Chrome-plated sheets are not suitable for welding and drawing. Chrome-plated sheets after painting are almost equivalent to tin-plated sheets.

2) The metal coating of the chrome-plated plate has a very high resistance, and the metal coating in the welding point area should be removed in advance during welding.

3) Chrome-plated plates may still rust in a humid environment, so use them as soon as possible after unpacking.

4) The outer surface of cans made of chrome-plated plates should be painted to prevent rust; the inner surface should also be painted unless the contents are engine oil and trial oil.

5) Chrome-plated plates do not have the anodic protection that tin-plated plates have. Appropriate protective measures should be taken to avoid scratches on the surface of the trial chrome-plated plates after canning and coating.

Download Google

1. The following information is required for ordering

2. Product Name:ETP/TFS

3. Thickness, width, length (plywood)

4. Brand: MR/SPCC/SPCE/D/L

5. Annealing method: BA/CA

6. Tempering degree: T1-T5 DR7-DR9

7. Tin coating amount: 1.1-11.2 g/㎡

8. Indicated quality: B/R/S/M

9. Order quantity: at least 25 tons

Quality assurance

1. Hydrophilic balance

2. Tin plating amount tester

3. spectrometer

4. Metallographic microscope

5. Tensile testing machine

6. Precision salt spray testing machine

7. Cupping test machine

8. Viscometer

Recommended tips:

Annealing method recommendation

1. BA has better tensile strength. BA has relatively stable performance in T2-T4.

2. CA has more uniform annealing, better hardness, and is more conducive to high-speed canning. If the customer's actual canning speed reaches more than 200 pieces/minute, BA will not work, affecting the customer's production output. CA tempering below T3 requires higher temperatures and longer times, and its performance is more difficult to control.

3. When the actual manufacturing speed is lower than 200 pieces/minute, CA customers may consider trying BA.

1) Example recommendation: For example, most factories cannot achieve the tempering degree T2.5 of CA-T2.5, or the scrap rate is relatively high. Most factories will recommend BA-T3.

2) Example recommendation: For example, most factories can achieve the tempering degree T3 of CA-T3, but some factories have a high scrap rate of CA-T3 due to different equipment. Customers will also be recommended to use BA-T3.5 or BA-T4.

4. Price: BA has certain price advantages over CA.

Width:

1. Most factories prefer a width of 800mm or more. If the width is less than 800mm, a surcharge is required. If you encounter a plywood with a length greater than 800mm and a width less than 800mm, can you consider exchanging the length and width?

Selection of rolls and plywood

1. Plywood is cut from rolls, and the factory can charge a corresponding processing fee. Domestic situation: The processing fee of can factories is lower than that of factories. If the situation abroad is similar, and the customer has the conditions, we can recommend the export of rolls.

2. The weight of the coils is generally around 4-9 tons. (If you have special requirements, you can inform us in advance) Generally, one container is loaded with 4 coils.

3. The weight of plywood is generally 1-3 tons. (If you have special requirements, you can inform us in advance)

Right angle edge and lace

1. The right angle edge is obtained by cross-cutting the coil. (Nothing special)

2. The lace is obtained by wave cutting of coils. There are many specifications and models of wave cutters, and the shapes of the lace obtained are also many. Therefore, customers who need wave cutting need to provide wave cutting drawings to see if they can match with the wave cutters currently available in the factory. If they cannot match, custom wave cutters are required, which usually takes a long time, about 3-6 months.

MR and SPCC materials

1. Usually MR is suitable for food grade, while SPCC is mostly used for miscellaneous tanks/chemical tanks.

2. The difference between MR and SPCC is that MR is low-carbon steel, while SPCC has a slightly higher carbon content. However, the domestic SPCC material is quite mature at present, and there is little difference between the two in terms of chemical content and performance.

Printing and lamination

1. Tin/chrome plate or tinplate substrate can be painted, printed or laminated on the original basis.

2. Coloring: What color should be painted on the outer layer, what color should be painted on the inner layer, and the weight of the coating. (The customer is also required to take photos for comparison to avoid color difference, or send samples for color comparison)

3. Printing: The customer needs to typeset the electronic document and specific requirements, and then the factory prints it out and typesets and prints it.

Email: 251596990@qq.com

Mob.: +86 130 2226 7000

Whatsapp: +8618806355666

Add.: Chow Tai Fook Financial Center, First Street, Binhai New Area, Tianjin, China