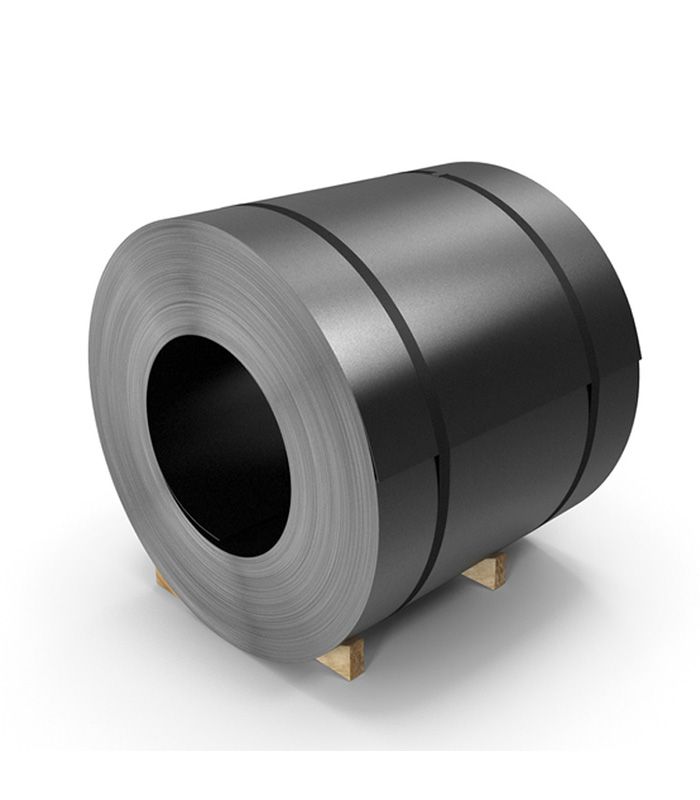

Hot Rolled Steel Coil and Plate

Hot Rolled Steel Coil and Plate

Product Description

Specifications:

Thickness: 1.2-25.4mm

Width: 600-2150mm

Package: The inner packing is plastic film and waterproof paper, outer packing is galvanized steel or coated steel, side shield, then wrapped with steel belt.

Materials: Carbon structural steel Q195, Q215, Q235, Q275 2.5-18 800-1100 C GB/T 700-2006.

Hot rolled steel coil and plate are made from slabs, heated and rolled by roughing and finishing units. Also named hot rolled carbon steel coil and plate.

Hot Rolled Steel Coil And Plate Process

The first step in the hot rolling process is to heat the steel, elemental or mineral mixture to a high temperature above its recrystallization temperature. Once it is heated above this point, the steel becomes ductile. It is then sent to a rolling machine where it can be easily shaped. With this hot-rolled carbon steel process, it can produce large quantities of steel in a single batch as minimal additional machining is required.

After carbon steel is processed, it is normalized by cooling to room temperature. The process of heating and slow cooling of steel changes the metal's microstructure, increasing its ductility and strength. When forming steel, increasing ductility is an important factor in obtaining the desired shape. The exact combination of elements added to the iron content determines the grade of steel and its unique strength, formability and hardness properties. Carbon and manganese are the two main additional elements that affect the outcome of a particular grade of material, but other elements can also play a key role.

Applications of Hot Rolled Sheet and Coil

Hot rolled sheets and coils are basic carbon steel products that are commonly used in applications:

● Agricultural equipment

● Auto parts

● Car frame

● Put up

● Pipe and Tubular

● Rail

● Strapping

● Stamping

● Transport infrastructure